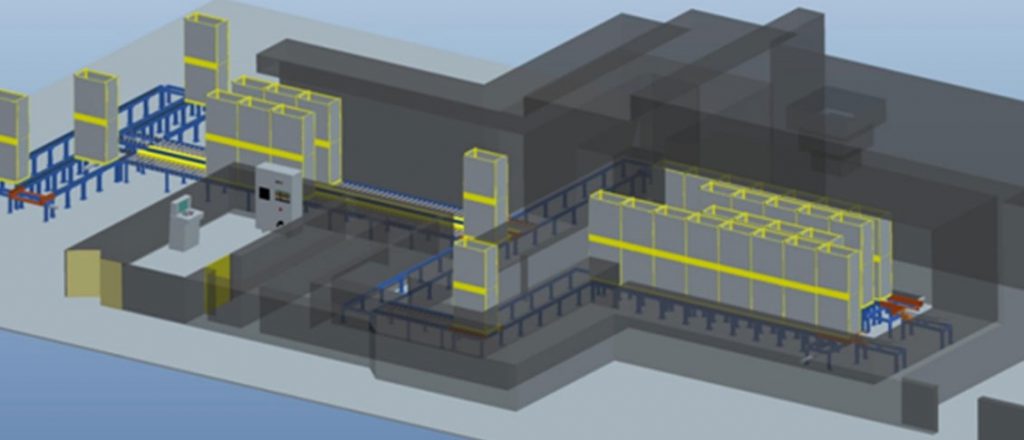

Updated Plant

Welcome to Akshargamma. Our state-of-the art facility at Ambernath, Maharashtra India is a multi-product gamma irradiation processing unit for innovative services to Gamma Sterilization and Gamma Irradiation Plant in India. Products sterility is retained indefinitely provided the package is undamaged.

With our most updated technology installed, we provide ODR (Over Dose Ratio) of less than 1.1. Due to this there will be no difference in Minimum and Maximum dose given and hence product will be processed undamaged without changing product properties. Unlike traditional design of plants that had over head conveyor systems, our plant has replaced the same with Power roller conveyor systems. This will solve the major issue of Oil / grease dropping over the boxes and damaging them.

We as a gamma irradiation plant in India, introduced Tote boxes there by replacing traditional Carrier system to process boxes. Damage arising due to pushing boxes by hydraulics into carriers in traditional plant design, will be completely resolved as we will process customers boxes by inserting them in our Tote boxes and eliminating carrier system there by eliminating the need of pushing boxes by hydraulic system. Our Tote boxes are uniquely designed in big sizes, allowing us to process boxes of any dimensions and also gunny bags, without having the customers to change their packing for Irradiation processing.

We have installed Seizer lift system for our Tote boxes, allowing Tote boxes to move up and down, due to which customers boxes will be inserted in Tote boxes through systematic and safe procedure, thereby preventing damage occurring due to throwing boxes from the top into the Tote boxes in currently operated plants due to lack of Seizer lift design where Tote box height is fixed and cannot be moved up or down.

With plans to set up 3 gamma irradiation plants under one roof, processing times will be reduced to 1/3rd as compared to current other plants in operation, and each product industry type will be irradiated in separate designated plants, thereby maintaining GMP, FDA, ISO and Hygiene norms to its best.

One of a kind Multipurpose plant design, thereby having ability to process multiple product types with no limitation, and providing Sterility Assurance Level (SAL) of 10-6.